Introduction

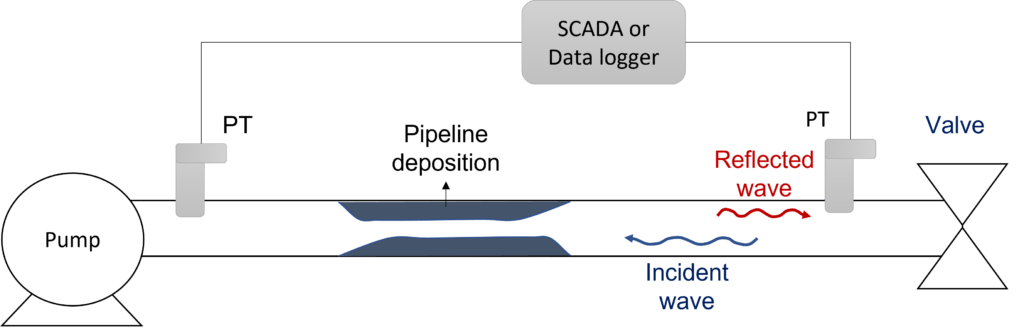

We at Bharat Flow Analytics got the opportunity to trial our wax or debris deposit estimation service with India’s biggest pipeline operator. We conducted a test on a pipeline section to analyze wax deposition along the entire 148 km length of the section. The pipeline diameter was 28 inches. The method used was Pressure Transient Analysis (PTA) which was developed in-house. The technology is fundamentally based on pressure wave movement phenomenon in a pipe. (ref: water hammer and transient).

PTA is an established technology, applied in oil and gas, hydropower and other industries. To apply this on a long oil pipeline we formulated a procedure that allowed for smooth testing in coordination with the operation teams at the two opeartion locations A and B (section end-points) as well as the company HQ.

PTA is an established technology, applied in oil and gas, hydropower and other industries. To apply this on a long oil pipeline we formulated a procedure that allowed for smooth testing in coordination with the operation teams at the two opeartion locations A and B (section end-points) as well as the company HQ.

Steps

The main tasks conducted are listed below:

▪ Flow was established using booster pump at one end (A). The other end (B) was the outlet.

▪ Valve at location B was operated to generate the pressure transient wave.

▪ An existing SCADA system provided the data from . The pipeline Data from SCADA system was obtained for multiple Pressure Transmitters (PT) and other instrumentation located on the section, including at both A and B.

▪ We used an optimization program that has been developed in-house to compute the diameter profile of VKPL section due to deposition. We verified the pressure response using this profile from location B’s PT data. The program was validated using location A’s PT data.

Advantages of using our service

- Non-intrusive method – no insertion in the pipeline.

- Provides quick and safe method of surveying pipelines.

- Long distances (~ 100 km or more) can be inspected within a short time.

- High accuracy depending on operating conditions (approx. 100 m detection granularity can be achieved).

- Helps reduce risk of stuck pigs.

- Wide range of applications in gas and oil pipelines like stuck pig finding, blockage detection, etc.